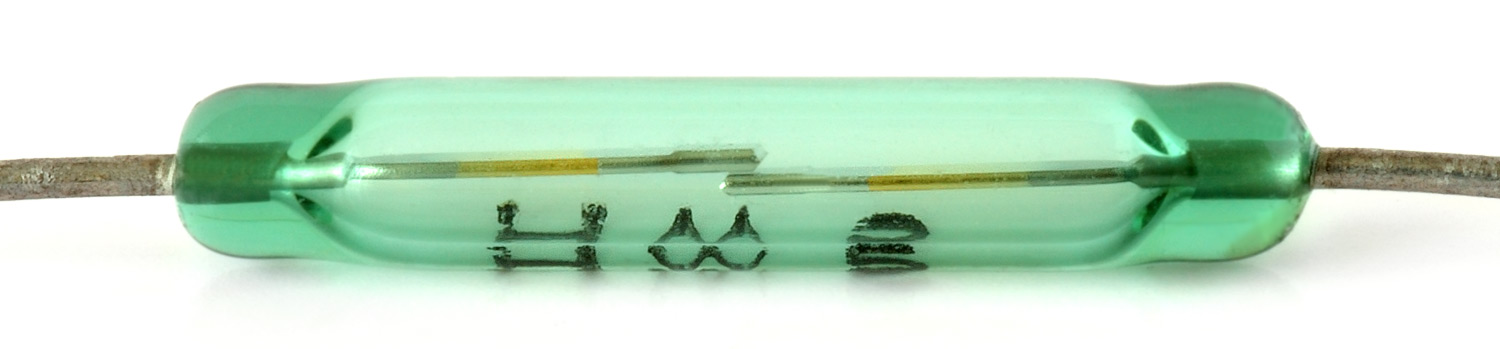

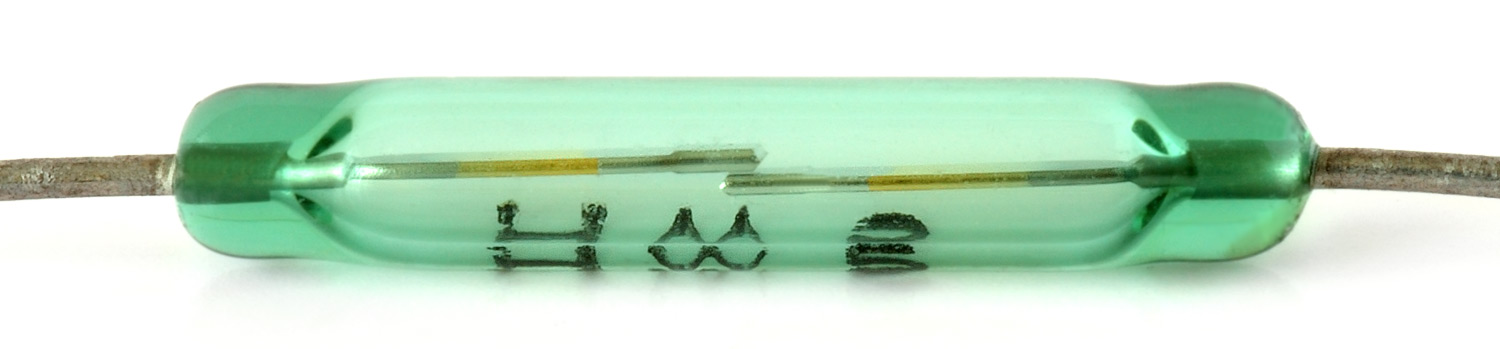

The reed switch is an electrical switch operated by an applied magnetic field. It was invented at Bell Telephone Laboratories in 1936 by W. B. Ellwood. It consists of a pair of contacts on ferrous metal reeds in a hermetically sealed glass envelope. The contacts may be normally open, closing when a magnetic field is present, or normally closed and opening when a magnetic field is applied. The switch may be actuated by a coil, making a reed relay,[1] or by bringing a magnet near to the switch. Once the magnet is pulled away from the switch, the reed switch will go back to its original position.

The reed switch included in the Electronics Component Kit is normally open, closing when a magnetic field is present.

An example of a reed switch’s application is to detect the opening of a door, when used as a proximity switch for a burglar alarm.

It can be combined with the included round magnet to create open/close switches, revolution counters in bicycle wheels and more.

Source: Wikipedia